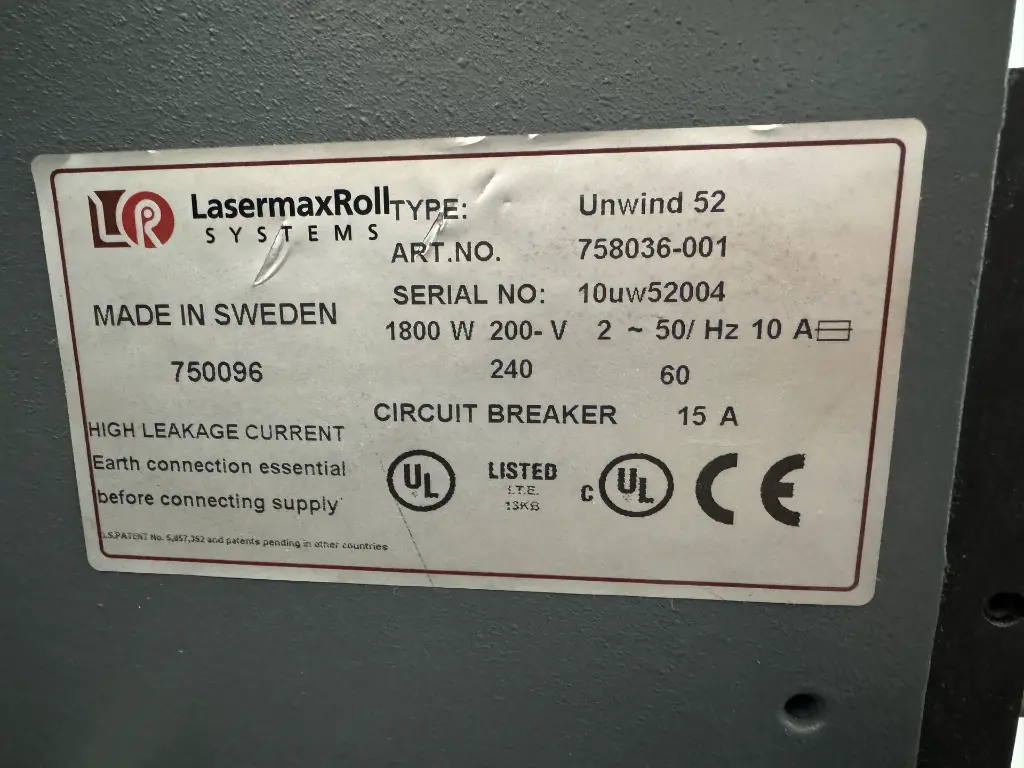

LasermaxRoll RS52 Unwinder

The RS52 Unwinder is designed for use in combination with modern high-speed laser printers. By feeding the printer from a roll instead of paper packs, it is possible to print for approximately 7 hours without interruption. Modern high-speed laser printers use about one pack of paper every 5 minutes (depending on the format).

Another advantage of this machine is that operators no longer need to handle heavy paper stacks, and the floor space required at the input side is minimized. The unwinder is easy to operate and requires minimal maintenance.

The RS52 Unwinder is part of the LASERMAX system, a solution for pre- and post-handling of paper in combination with high-speed printers.

Year of manufacturing: 2004

Function

Function

The unwinder is suitable for paper rolls with a maximum diameter of 1320 mm and a maximum width of 520 mm. The paper is unwound using an electric motor that drives an axle located inside the paper roll. As the roll decreases in size, the axle spins faster. Various sensors in the machine monitor the paper movement and ensure that the correct rotation speed is applied.

The axle inside the paper roll is a pneumatic (air) axle that expands when air is pumped into it, thereby securing the paper roll onto the axle. The compressed air for this axle is supplied by a compressor built into the machine. An electrically operated lifting device raises the paper roll to the correct position, and two clamp handles lock the air axle in place. To avoid damage, always follow the correct procedure when changing paper rolls. Several sensors ensure that the air axle is correctly positioned and the safety cover is closed; otherwise, the machine will stop.

The paper path must be hung in a loop downwards into the unwinder to act as a buffer when starting the laser printer. Three photocells monitor the size of the paper loop, and the machine control system adjusts the speed accordingly.

Operation and Safety

The stop diameter can be set in the program so that the unwinder stops the printer at the right moment when the set diameter is reached. The unwinder stops automatically and emits an acoustic signal.

When a new roll is loaded, the new paper can be attached to the trailing edge of the previous roll using special splice tape. This splice tape is specially developed and does not cause any problems with the operation of the laser printer.

Note:

Do not use ordinary tape for splicing, as this can damage the laser printer.

As a preventive measure, a special sensor is mounted on the machine to monitor the paper path and stop the machine if the paper is not correctly positioned. The sensitivity of this sensor must be set individually for each paper type. The splice sensor can be switched ON and OFF with the “SPLICE FUNCTION” button.